Insights into our mechanical engineering company

Here in Nieheim!

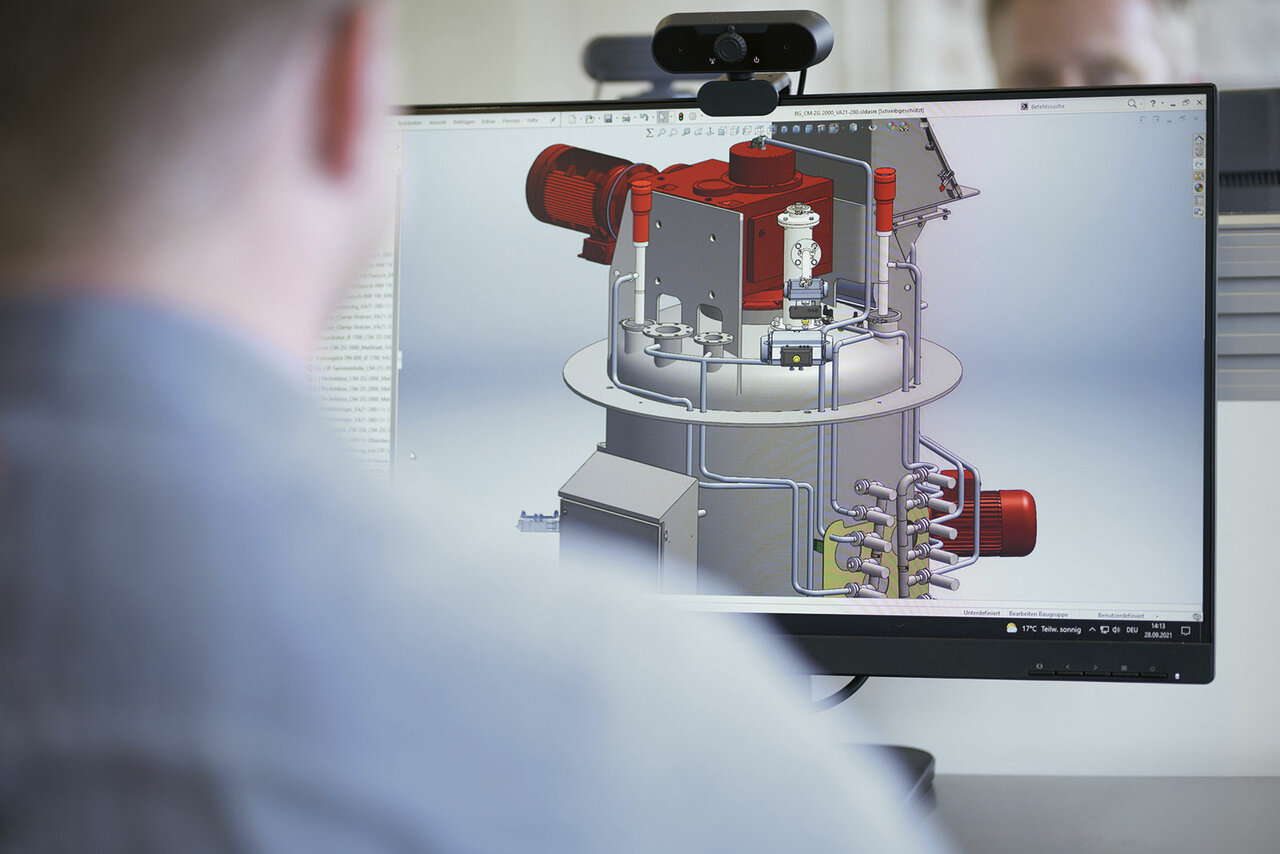

Visit us in north-eastern North Rhine-Westphalia and get to know our modern company. We offer maximum transparency in our processes and insights into our 5,000 m² development environment, where innovative technology solutions are created. A friendly consulting team guides you from the initial idea to the project’s completion and conducts practical trials in our in-house technology centre. Mobile test machines support your development processes directly on-site.

RUBERG is a family-run business with 65 employees and an open, creative atmosphere. We foster personal, equal-level interactions with customers, partners, suppliers and employees. High standards for safety and quality are second nature to us.

As a training company, we ensure qualified new talent, invest in new technologies and optimise our resource management for greater sustainability.