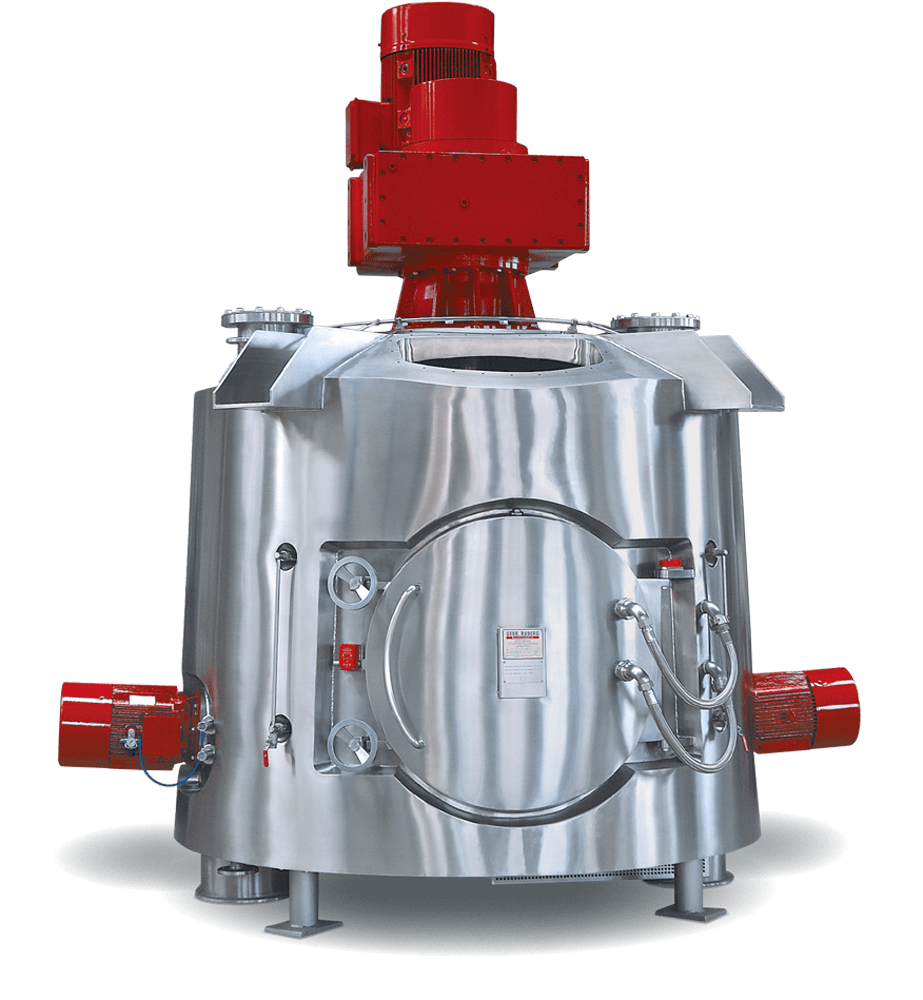

RCM series

The spectrum of possible applications ranges from the processing of highly sensitive products in the pharmaceutical, fine chemical and food industries to bulk materials in the chemical, building materials, plastics and animal feed industries. A wide range of design variants with adapted material and machining standards is available.

Heating, cooling, drying, conditioning, homogenizing, aerating and degassing, crystallizing, foaming, etc. are just a few tasks that the RUBERG reactor mixer is designed for. These mixers deliver high performance and flexibility, Special surfaces, joint-free processing as well as rotationally symmetrical radii enable germ-free and sterile production. The reactor chamber is equipped with a mixing unit based on the principle of the RUBERG precision batch mixer and thus represents an ideal combination for process engineering processes. Sensitive granulates, fine powders, low to high viscosity liquids, are treated extremely gently and effectively.

Info & downloads

Example tasks:

- Mixing

- Batch mixing

- Deagglomeration

- Inerting

- Homogenizing

- Dispersion

- Drying

- Compacting

- CIP

Application areas:

- Baby food

- Baking agents

- Chemistry

- Spices

- Plastics

- Food

- Pharmacy

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.