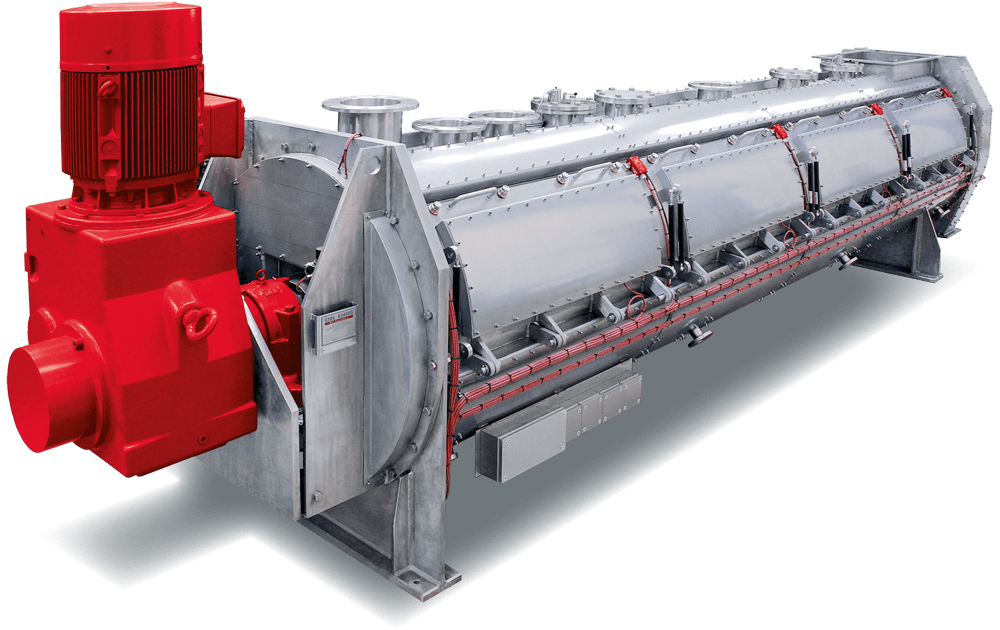

DLM series

From 0.5 – 750 m3/h throughput with a mixing chamber volume of 70 – 7200 litres. In corresponding, high-quality stainless or special steels. Individually adjustable mixing tools allow a variable residence time of the product in the mixing chamber. Installation horizontal or up to 45 degrees slope. Low operating costs due to robust design. Inspection flaps along the entire length of the mixer for cleaning and maintenance. Residual emptying > 98%, depending on design and mixing tools.

Processing options: Loosening, homogenizing, agglomerating, moistening, conditioning, liquefying, gluing, deagglomerating, greasing, granulating, dispersing, neutralizing, molassesing, emulsifying, dissolving, coating

Info & downloads

Example tasks:

- Mixing

- Homogenizing

- Inerting

- Coating

Application areas:

- Building materials

- Animal feed

- Cereals

Industries & products

Baby food

Baking agents

Chemistry

Spices

Coffee & tea

Plastics

Food

Oilseeds

Pharmacy

Ask us!

Would you like a consultation, more information on this machine solution or are you generally looking for a customised overall solution? – Get in touch with us now... Of course, you can also call us directly: Phone number: +49 (0) 5274-98510-0.

We look forward to your inquiry.