Efficient development processes

From the idea to the finished machine

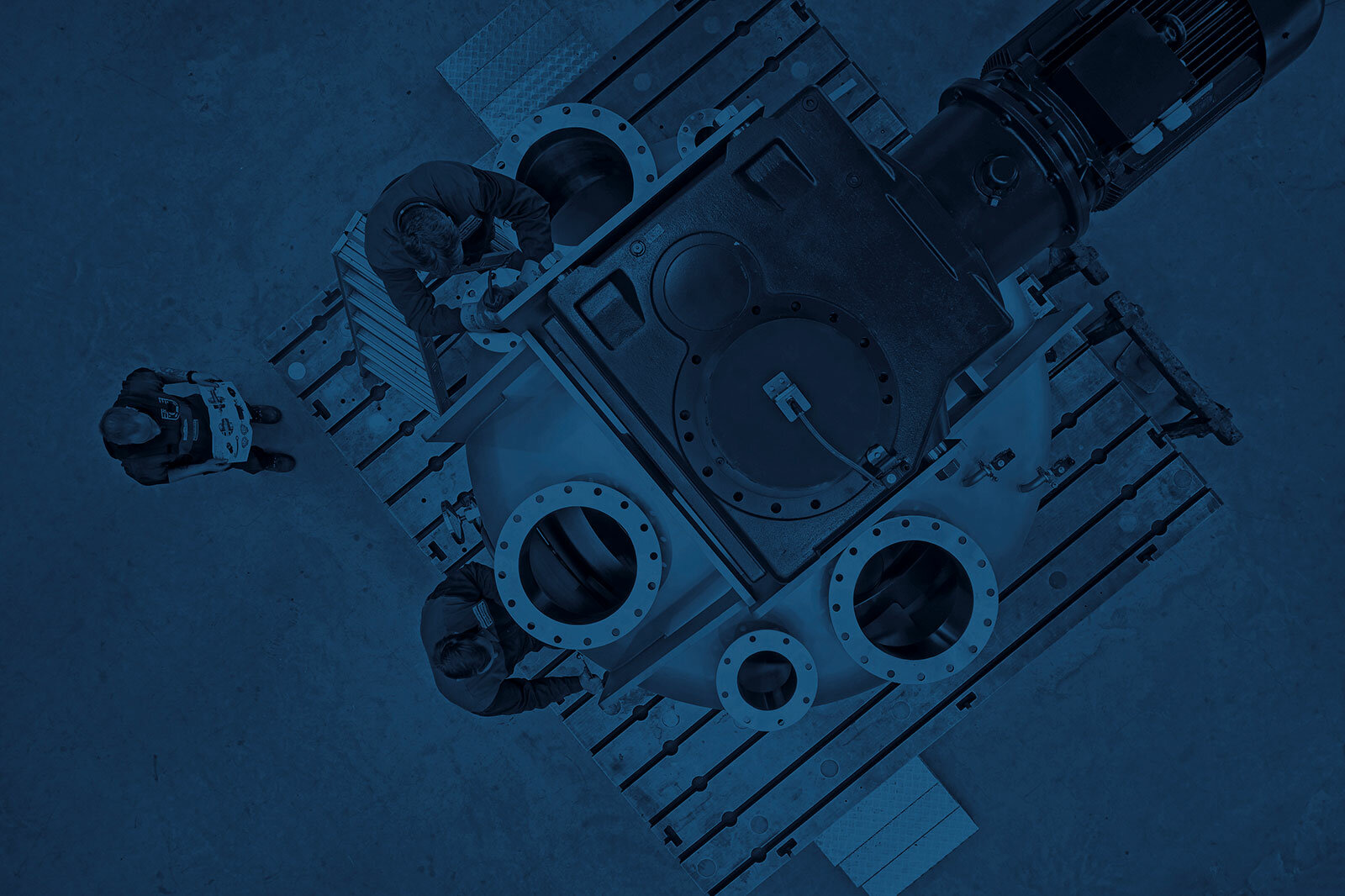

RUBERG accompanies its customers from the first contact, the exploratory discussions, the ideation phase through planning, development and manufacturing, all the way to logistical tasks, post-delivery support and assembly. The collaboration with the client is characterised by a trustful relationship, flexibility and consulting expertise.

The heart of our planning and development services is the RUBERG Technology Centre with its attached laboratory. The link between product development and production allows us to conduct practical mixing, cleaning and separation tests on 350 m³. Here, procedures for production are optimised and process parameters for the planning and development of customer systems are determined. This means more certainty in planning before the final construction.